Dry Lubrication Technology for Chain Conveyors in the Bottling Industry

TM Smart Track dry lubricant, provided by THONHAUSER is a recently developed, pH-neutral and fully synthetic dry chain lubricant, specifically designed for the use on plastic chains for the transportation of product packages in the food and beverage industry, where an anhydrous operation is desired (PET-bottles, cans, cartoon package, one-way-glass, etc.)

TM Smart Track dry lubrication system has many advantages over other dry lubrication systems:

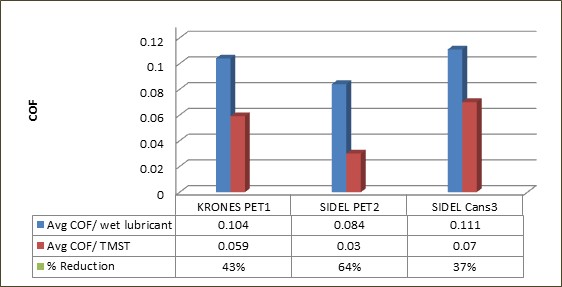

Brief Case Study on the significant reduction of coefficient of friction after switching from wet to TMST dry lubricant:

Dry Lubrication Systems in general:

Today, with the increasing needs to conserve water and minimize waste water, new technology of dry lubrication was developed. The dry lubrication systems result in completely dry conditions, which by role:

- Eliminate fresh water consumption and reduce waste-water treatment.

- Improve hygiene & operational safety (No water, No foam, No growth of microorganisms, no slippery floors)

- Lower friction coefficient leading to minimize fallen bottles and improve line efficiency.

- Result in better and smoother running of the conveyors, where wear & tear are minimal.

- No formation of aerosol that is usually formed when spraying wet lubricant on conveyors.